One cut ahead with us!

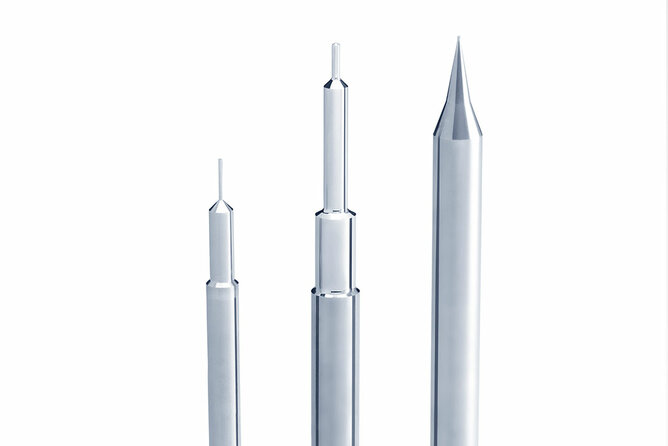

Semi-finished products and blanks for the cutting tool industry

Our range of services is the ideal supplement for manufacturers of cutting tools. We supply tool grinding shops with individually ground semi-finished products and step blanks. Our solution chain is specifically geared to the needs of tool grinders.

We keep an extensive stock of carbide rods and can advise you right from the development stage on the best selection for specific drilling, milling or reaming tasks.

Our process chain with centerless and peeling grinding enables the processing of raw bars and ensures the best possible material availability.

Thanks to our flexibility, we can process orders very quickly and extremely economically with the help of our own automation concepts.

We know what our customers expect of perfect semi-finished products and the requirements of different machining tasks for the design of the cutting tool blanks.

How to benefit from our service:

We carry an extensive stock of high quality carbide rounds and advise our customers on the appropriate selection for their application.

Our close cooperation with material manufacturers and our vertical range of manufacture ensure the ability to act - even in times of material shortage.

We guarantee offers within 24 hours and deliveries within a few days.

Express deliveries are possible by arrangement.

We take care of your material planning. And you save yourself a material warehouse and a lot of tied-up capital!

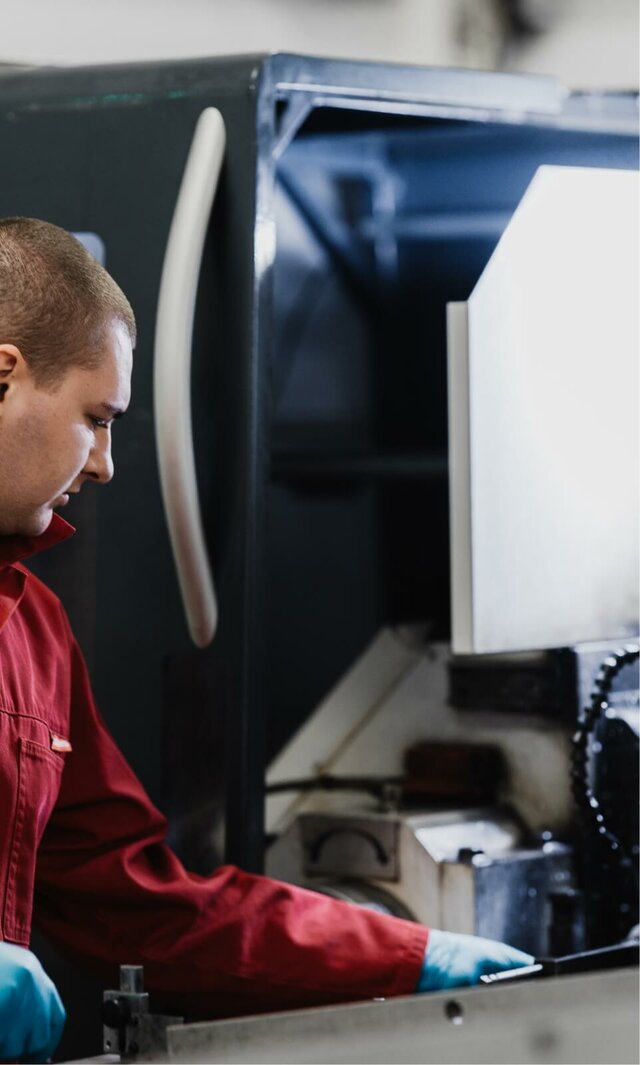

Wir verfügen ausschließlich über modernste Maschinen und Messmittel und garantieren engste Toleranzen – auch in Serie!

We prepare the blanks perfectly for you. And you can take care of the tool geometry. That saves time and costs!

For reamers and drills, we have developed a special finish of surfaces, which gives your tool performance advantages.

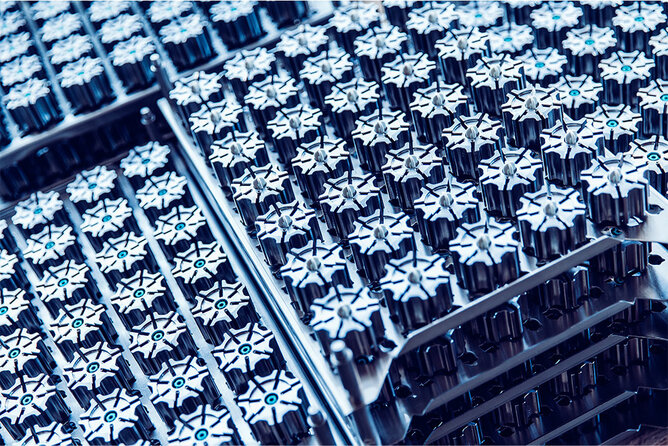

Best surfaces

Polished in perfection

Examples from our production

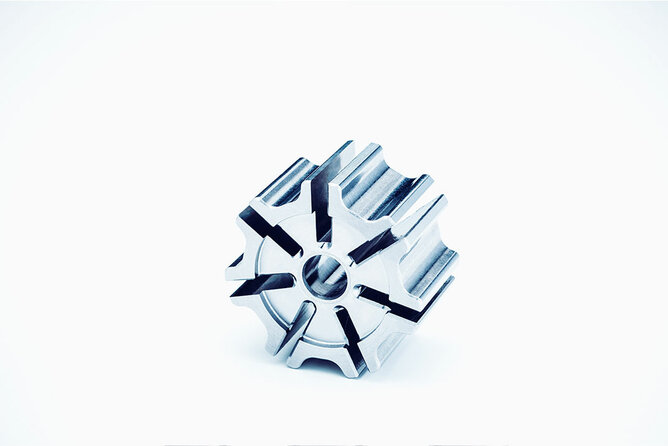

Strong materials. Many geometries.

Precision parts made of carbide and ceramic

Our technologies and tools enable the high-precision processing of particularly wear-resistant materials. We manufacture precision parts from hard metals, ceramics and tungsten/molybdenum according to customer drawings. We offer a wide range of geometries in the Ø range from 0.3 to 25 mm and component lengths of up to 300 mm. The design is based on the customer's drawing. We guarantee the tightest tolerances and the best surfaces.

Our customers include clients from a wide variety of industries such as mechanical engineering, aviation, medical and energy technology as well as the jewelry and watchmaking industry.

How to benefit from our service:

We carry an extensive stock of high quality materials and advise our customers on the appropriate selection for their application.

Our close cooperation with material manufacturers and our vertical range of manufacture ensure the ability to act - even in times of material shortage.

We guarantee offers within 24 hours and enable deliveries within a few days.

Express deliveries are possible by arrangement.

We take care of your material planning. And you save yourself a material warehouse and a lot of tied-up capital!

We have only the most modern machines and measuring equipment and guarantee the tightest tolerances - even in series!

Projects

Products

Precision parts made from different materials

The final touch makes all the difference!

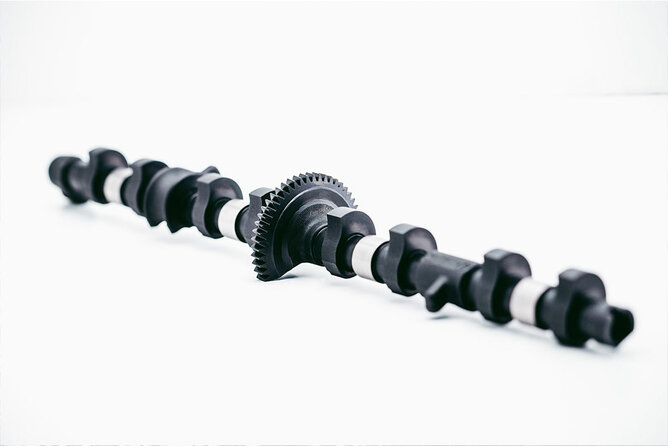

Precision machining of components

We refine turned, milled or formed parts as well as cast or sintered blanks with a wide range of grinding processes. This allows us to create tight tolerance zones, specific surface qualities and concentricity properties that cannot be achieved with alternative manufacturing processes.

In addition to ordinary steels, we often deal with titanium or aluminum alloys as well as nickel materials that are difficult to machine, tungsten or molybdenum.

Our process chain includes the process steps of straightening, grinding, impregnating and cleaning. Our range of processing includes technology-spanning smallest parts from Ø 1 mm as well as workpieces up to Ø 200 mm and length 2,000 mm.

Through the use of stable production machines and specially developed automation solutions, small batch sizes as well as large series can run through our factory under economical conditions.

How to benefit from our service:

We have only the most modern machines and measuring equipment and guarantee the tightest tolerances - even in series!

We have flexible (and in some cases specially developed) automation systems with which series components can be processed economically and efficiently.

We bring our knowledge and years of experience in grinding components into your process chain.

Projects

Products

components according to individual customer requirements.